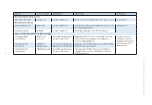

Lake Eyre Basin Rivers 186 than investigating other technologies that might reduce gas demand – such as switching electricity and domestic heating or cooking away from gas to more sustainable technologies such as solar thermal electricity or solar hot water. The recent trends in conventional and CSG reserves in Queensland (Fig. 19.9) show a downward trend for conventional gas and a relatively modest total of 474 PJ at the end of 2013. In addition, Santos, Beach Energy and Drillsearch all report 1570 PJ of gas in their SA operations in the Cooper-Eromanga Basin (current gas production is 109 PJ/year Table 19.1). There has been extraordinary growth in CSG reserves in the Surat and Bowen Basins in Queensland, with the Surat Basin rising from 374 PJ in December 2004 to 32 795 PJ in June 2014. This makes CSG reserves comparable in scale to those off the northern coast of Australia (e.g. the Carnarvon, Browse and Bonaparte basins), underpinning three major liquefied natural gas export projects on Curtis Island near Gladstone in Queensland. While there are no formally reported CSG or shale gas reserves within the Lake Eyre Basin yet (as of 2013), companies are exploring the Galilee and other basins. Given the extensive exploration licences issued by the Queensland Government (e.g. Western Rivers Alliance 2016), there is a good probability that the CSG history from the Bowen and Surat Basins could be repeated inside the Lake Eyre Basin (especially the Galilee Basin), leading to new frontiers for CSG and potentially shale gas developments and associated environmental risks for the Lake Eyre Basin. Coal seam gas (CSG) in Queensland The CSG industry remains highly controversial, with major environmental, economic and social risks and impacts. This relates to its exploration and development, which can have impacts on groundwater levels (i.e. heads or pressures) and groundwater quality (especially, salts, metals, organics and radionuclides), as well as the potentially greater release of methane to the environment due to groundwater impacts (Drinkwater et al. 2014). CSG is produced underground, where it is trapped in coal seams. To release this gas, wells need to be established, sometimes close to each other (~0.6–1 km), involving a platform and a road and pipe network to service the well and take away the gas and water produced (Fig. 19.10). To extract the gas from deep underground, groundwater invariably needs to be extracted first to reduce water pressure and allow the flow of the gas to a well from where it is extracted. This groundwater needs to be stored or managed above ground. Average groundwater extraction produced for the past 10 years (2004–2014) is respectively 50.0 and 121.6 ML/PJ for CSG in the Bowen and Surat basins. Water extraction is higher in the earlier phase of CSG development and then declines over time (Drinkwater 2015). Occasionally where the coal has low permeability, water with small quantities of sand and a wide array of chemicals (e.g. various salts, heavy metals, organics and biocides, depending on the biogeochemistry involved) is injected under extremely high pressure to hydrologically fracture and control the behaviour of the coal and allow the gas to escape to a nearby well – a process commonly known as ‘fracking’. This water also needs to be removed and managed (e.g. treated, discharged to surface water and sold to local users such as farmers), but invariably contains residual contamination from the complex mix of chemicals. There are inevitable environmental and social risks in these developments, which remain poorly

Downloaded from CSIRO with access from at 216.73.216.176 on Nov 27, 2025, 7:56 PM. (c) CSIRO Publishing